Building a deck? The Oregon Prescriptive Deck Plan is a great resource that applies to a simple, straight-forward, code approved deck.

You can get a quote from us by reaching out through our Contact page. Or select from these links to research estimates; Home Advisor, Cost to Install Stair Railing and Costimates, How much does Aluminum Railing Cost? or Lowe’s Stairs and Railings. You will probably find many other links as well to gather ideas for your project.

The first things to consider for your railings are safety and code compliance in your area. Waterproof Decks of Oregon typically installs Stainless Cable Rail, Aluminum Picket and Rail or Wood Picket and Rail on decks and stairs, with many styles and colors available. For more research, here is a link to Durarail, a Duradek product, and from HGTV 31 Deck Railing Design Ideas. Also a word of caution. Horizontal baluster systems look like a ladder to children and a footrest to adults. This can stretch horizontal cable and bend or break horizontal aluminum, steel or wood balusters.

New railings can be attached to existing decks and patios to add where none existed before, to bring a railing system up to modern safety and code compliance or to simply change the style. Here are some links you can use to evaluate the process; How to Add a Rail to an Existing Deck, How to Install Deck Railing, Deck Rail Post Attachment, Different Types of Deck Railing Post Anchors, How to Attach 4×4 Post to Deck

Maintenance will be different depending on the railing material but the key to maintaining any deck rail system is frequent inspections. For safety the components need to be a certain distance apart, so things that are loose must be made tight or stable. Cable railing may need to be tightened to remove slack (horizontal things look like ladders to children and footrests to adults), wood fasteners may need tightened or rotted wood replaced, debris may need to be removed or a finish may need reapplied. Wood is typically the most cost-effective railing system up front, but maintenance over time will be more frequent, intensive and expensive. Railing systems made from stainless steel, aluminum, and glass can be easily maintained but are initially more expensive.

In all systems the correct methods of fastening the posts to the deck framing is of key importance to safety and longevity. Simple cleaning will also depend on the railing material, and it is important to know what should and should not be used as a cleaner. Also consider your safety. If you are high enough to need railings, you are also high enough to be injured from a fall while cleaning them. Here are some links to consider; Maintaining Your Deck Railing System, How to Maintain and Clean Your Cable Railing, Glass Railing Cleaning and Maintenance Guide, Maintenance-Free Deck Railings, How to Care for Your Wood Railing, Deck Maintenance & Care for DIYers

Duradek Waterproof Membrane is available in patterns and colors that are for the most part neutrals, to complement existing features without overpowering them. This gives the railing an opportunity to stand out as a feature or blend in with existing details like gutters and trim, door and window moldings, etc. Railing can be fascia mounted to the edge of the deck to maximize space and ensure there are no penetrations through the membrane, or surface mounted with special treatment and precautions in consideration of the membrane.

Either type will carry the full warranty of the material and installation. A wood railing can easily be painted or stained to punch-up the look but still have a comfortable, traditional style. Aluminum railing, commonly available in black or white, (and be powder coated in a range of colors at an additional expense) will usually have a more streamlined, modern look, as will stainless cable railing and glass balustrade railing that are less distracting and provide a more unobstructed view. Look through our Recent Projects page to see some examples of these railings with membrane surfaces. Here are some further links to investigate; Fascia Mount vs Top Mount Railings, Durarail -Rail Mounting Types – Considerations, Building Sturdy Deck Railings

While many railing systems have very long, lifetime or limited lifetime warranties, it is very important to understand exactly what that means by each manufacturer. Almost all railings will call out installation within a certain distance from bodies of salt water, alterations, lack of maintenance, fire, floods, acts of God and so on. Others will include abrasion from blowing sand, corrosion from dissimilar metals, pool chemicals, road deicers, or air pollutants. Some will call out very specific things such as the number of hours in the sun at a certain latitude facing certain directions and acceptable rates of color or finish fading.

For peace of mind the most important things you can do are to ask questions, have an installer you trust, have a product that the installer trusts, read and understand the warranty and do inspections of the railing system at least twice a year so you are aware of any issues that will affect the warranty and the safety of the railing system, that it may be addressed quickly and without making something worse.

Guard rail attachment is influenced more by local building code than Duradek requirements. It is preferable to fascia mount railing to avoid piercing the membrane. However, there are surface mounted guard rail installation techniques onto Duradek that perform successfully. Either way your Duradek will have its full material and installation warranty. Our recommendation is to have your Duradek installer also install your guard rails. This way you have a single source for your warranty protection, and you know for sure your guard railing will be installed with consideration to the vinyl membrane.

Duradek is a 60 mil flexible, inert PVC composite waterproof membrane that is chemically and dimensionally stable. The membrane is adhesive bonded to prepared horizontal (walkable) surfaces and adhesive bonded or mechanically attached to vertical surfaces. Duradek seams are very resilient, using a 3-weld system with a 3/4″ seam overlap, back welded, then a main weld, and completing the seam with a cap weld. This makes a durable, continuous waterproof surface. For more information see the Installation Details on the Duradek website and download the two informational .PDF detail graphics at the bottom of that page.

Duradek waterproof membrane can be installed over certain cement boards, Durock being the brand we recommend. It can also be applied to completely cured and unsealed concrete that is above grade (not ‘slab-on-grade’), properly sloped for drainage and free from defects (or repairable). The surface must also be free of any dust, dirt, grease, wax, oil, paint or other contaminants and have a relatively smooth, steel troweled finish. Older existing concrete will usually need some attention to achieve an acceptable surface.

Waterproof Membrane must be installed onto a stable continuous surface, so cedar and composite decking are both unsuitable substrates. However, it may be possible to install suitable ACX plywood over the deck boards, to create a suitable surface. The deck framing and existing deck boards would have to be sound or repairable with sufficient space below any door jambs for additional material. You would compare this against removing the deck boards, installing a suitable substrate, then installing the membrane

Yes, there are ways to build a “floating deck” on top of a membrane surface! And it’s also possible to dismantle an existing floating deck to repair or replace existing waterproof membranes that are underneath. We have done both.

We will work with your designer or architect or help you find one if you like. Or we can use our resources and build it into the price of the project. There are an enormous variety of architectural styles and products available but careful planning is often necessary to keep costs and delays manageable. We also stay aware of current building codes and construction best practices and can assist navigating the building permit process when needed.

For more research see these links; How to Build Deck Plans, Building a Deck that Meets Code, DeckWise Product Specifications, Permits for Building a Deck, and for very specific details that are approved in Oregon see the Oregon Prescriptive Deck Plan. This link does not cover all available options for building a deck, but it does cover basic accepted footing, post, beam, joist, ledger, and component attachment methods and hardware.

If other repairs are needed and are within our scope of expertise, we can include that in our quote for your deck upgrade. While our Estimator is at the site visit, please discuss any issues and ask any questions you may have. Our Estimator will also take photographs to document the potential scope of work and attempt to make assessments of things to address.

Understand that this site visit is not exhaustive and other unknown issues may be exposed during the project that are not included in the quote. This requires a Change Order, proposing a repair option(s) that will charge for materials and labor to complete the unplanned repair and must be agreed to and usually paid for before work can continue.

These types of issues frequently involve hidden water damage that is exposed as other materials are removed, sometimes in deck framing, beneath posts, sometimes behind the exterior wall, etc. More good information in these links; Repair or Replace a Damaged Deck?, How to Repair a Deck, The Deck Repair Process: A Comprehensive Guide, DIY Fixes from the Boards to the Railings, Replace Deck Boards and Repair Your Deck, 8 Things To Know About Replacing A Deck, Deck Replacement: When It’s Needed & What to Do,

Waterproof Membrane can be directly installed over Cement Board (Durock is recommended). It cannot be directly glued /installed to rigid insulation. A layer of acceptable plywood must be installed over the rigid insulation to adhere the Duradek. Rigid insulation is not designed to be walked on directly.

Options would have to be assessed. Depending on the type and condition of the coating, the coating could be removed. If the substrate requires too much preparation to become useable it may be possible to apply an additional substrate layer over it. If not the, substrate would have to be removed and replaced with new substrate for the Duradek membrane.

We use Mapei Planipatch, Ardex Feather Finish and autobody filler products to bridge the surfaces.

Duradek is a fully adhered system. Meaning that it is fully bonded to the substrate and mechanically fastened around the perimeter.

It is important not to overtighten the tongue and groove portion of the plywood as that will cause that edge of the plywood (the 8′ edge) to swell, heave and telegraph through the Duradek. The butt joints can be tight.

Duradek does not have a specific “transition” membrane for this scenario. However, we do have recommendations for isolation products that can be used to separate the vapor barrier from Duradek. This is only necessary when Duradek has an incompatible product coming into direct contact with it. Foil tape is a very common product used to isolate Duradek from an incompatible product or material.

A clip, when installed correctly, will not fall off. If it does fall off it’s because it has been pried off or damaged. It can be reinstalled and glued into place.

Yes. All “bitumen” (asphalt or asphalt tar) based products, including Blueskin, are not compatible with Duradek or any other sheet PVC.

Most urethane or butyl-based peel and sticks are suitable.

Duradek membrane is not compatible with bitumen-based (asphalt or asphalt tar) products.

When replacing Duradek, most times if the plywood underneath is dry and stable it can be re-used. If any delamination of the plywood occurs, filling and sanding is usually adequate.

Minimum slope is 2% or 1/4 inch per foot. If there is too little slope our installers may be able to create slope by a variety of methods that would be project specific.

For a new installation 3/4″ T&G ACX plywood or cement board meeting ASTM C1325, Durock being the brand we recommend. Please see our Substrate Requirements.

Yes, we have details for the scupper (Drawing DR-03) and drain details (Drawing DR-02). We have a collection of drawings for more than 50 specific details.

Please inquire about Detail Drawing IS-04.

If there is a risk of moisture below, there must be adequate ventilation to avoid trapping the moisture below the membrane.

Attachment to an appropriate substrate, ventilation, minimum slope for water runoff, and tie-ins to the existing building envelope are typical considerations for a Waterproof Membrane installation.

Ideally there is adequate slope built into the deck of 1/4″ per linear foot away from the building. However, Duradek installers may be able to create slope by a variety of methods that would be project specific.

Duradek waterproofing is fully adhered in the field of the deck and mechanically fastened around the perimeter of the deck. Duradek seams are a 3-weld system with a 3/4″ seam overlap, back welded, then the main weld, completing the seam with a cap weld. This makes a resilient, continuous, waterproof membrane.

Yes, absolutely. Here is a link to some Recent Projects.

Small projects can take as little as 1-2 days on site. Larger or more complicated projects can take up to several weeks on site.

Typically 2-3 person crews consisting of a Lead and Helper or Lead, Helper and Apprentice. These terms are only relevant to Duradek and related installations as what we do is a specialty trade, outside of general construction. All of our personnel have a background in construction techniques and practices as well as specific training to install Duradek, railing and other specialty products. On larger projects we may have more than one crew working during certain phases.

Currin Construction LLC has been in business since 2014 and DBA Waterproof Decks of Oregon has waterproofed over 350 decks since 2017.

For commercial projects like these a control plan should be developed to help minimize impact and maximize continuity of business. Guest, resident, customer and employee access and parking, signage, temporary workspaces and maintaining a safe and professional presence must work alongside contractor access, material storage and staging, noise, dust and debris control, security and other needs. There should be expectations and timelines as well as options, flexibility and compromise, as there is always the possibility of unexpected issues arising that cannot be planned for.

Assuming the site is safe in all other aspects, the Duradek surface is ready for traffic as soon as it’s glued in place!

Yes, temperature permitting. Duradek adhesives must be applied at temperatures above 40 degrees F.

Training and experience are key to ensuring your Duradek installation is beautiful and high-quality. Duradek is only available through manufacturer distribution. In order to provide and install Duradek, Waterproof Decks of Oregon installers are certified through hands-on training at Duradek NW in Auburn, WA. During the training, our installers learn the basics of Duradek installation, including welding seams, surface preparation, adhering Duradek to surfaces, and handling details such as inside and outside corners, doors, thresholds, posts, and drains. We also engage in ongoing training at our facility and frequently review technical bulletins and updates. Most of our installers have been with us for many years, they are experts, and are gaining more experience in the field every day.

Yes it is! Duradek Ultra offers a 15-year waterproofing warranty, as well as a 5-year color warranty. When your project is complete, we mail you a warranty certificate. Waterproof Decks of Oregon also offers a 15-year workmanship warranty on Duradek installations. Duradek warranties are physical and transferable, meaning that even if you sell your home, you can hand them the warranty certificate and the new owners will still be protected for the duration of its term. This makes Duradek a valuable investment, as it adds value to your home and provides peace of mind for the new owners.

Duradek is the only vinyl manufacturer that offers a transferable warranty. It is also not pro-rated. See details on duradek.com/duradek-warranty. Also see our article on Evaluating a Vinyl Decking Warranty. Should something happen under the vinyl warranty, Duradek covers the cost of replacement of the vinyl for the entire 15 years and also covers the labor to replace the vinyl for 10 years. We believe this to be excellent coverage as compared to other vinyl decking warranties out there that do not cover the labor at all or are pro-rated for material

Duradek Waterproof Membrane is 6′ or 72″ wide. For a deck installation the membrane will lap vertically 6″ behind the siding and roll over the outside edge of the deck 2″ making the maximum depth for a deck with no seams 64″ or 5′ 4″. For deeper decks it may be more economical to run the seams parallel to the structure, or perpendicular to the structure, to minimize waste. Where two pieces of Duradek meet an additional 3/4″ of each section will be used to heat weld a seam.

Like any deck surface, the amount of heat that the vinyl absorbs or reflects will depend on the color. Darker colors will hold more heat, lighter colors will reflect more heat. For projects where surface heat is a concern, Duradek has a Cool-Dek collection of our ‘coolest’ colors that have the highest SRI (Solar Reflectivity Index). See our Cool-Dek page for details.

There is the option of covering aged vinyl with the application of a specialty deck coating using our recoating instructions. This can be done by the homeowner. Additionally, a new vinyl color can be applied to the existing Duradek when the applicator follows our recommended “vinyl over vinyl” installation instructions.

Duradek vinyl has been manufactured in North America since 1974 and has been used to waterproof over 180,000,000 sq.ft. of surfaces for over half a million homes.

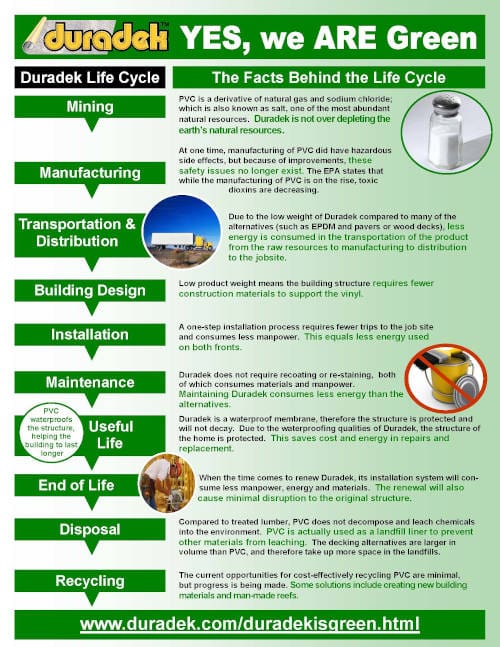

This is a very good question and I’m sure there are as many opinions as there are science and facts. I would do your own research, but here are some places to start; Yes, Vinyl IS Green, When You Think Environmentally Friendly, Think Vinyl, and this article from the National Library of Medicine A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling

Like any deck surface, the amount of heat that the vinyl absorbs or reflects will depend on the color. Darker colors will hold more heat, lighter colors will reflect more heat. For projects where surface heat is a concern, Duradek has a Cool-Dek collection of our ‘coolest’ colors that have the highest SRI (Solar Reflectivity Index). See our Cool-Dek page for details.

Duradek is only available from an authorized dealer as an installed product.

The Duradek membrane will allow moisture transmission in the form of gas to permeate through the membrane, but not back the other way. So, any moisture that may be trapped between the substrate and the membrane will escape in a matter of several hours to 2 days. Once it’s gone there will not be any further moisture that will come in from the outside. Should there be any small holes in the membrane from damage, it will not be able to get under the vinyl as the vinyl is fully adhered to the substrate with adhesive.

Yes – Duradek is not available for purchase to anyone who is not an authorized Duradek Dealer/Installer. It is not a DIY Product. Duradek installers are trained in all aspects of the installation.

Duradek is a ‘walkable’ waterproof membrane with a slip-resistant surface that is also easy to clean. It is chemically stable. It meets roofing standards. It can be installed in almost any temperature and is immediately useable as a walkable, waterproof surface. It is highly elastic, moves with the substrate it is attached to and it will not crack. It is relatively attractive, very resistant to damage and is heat-weld repairable if needed. It will not rot. It will not delaminate. it will not chemically separate. It does not need to be ‘re-coated’. It has a serviceable life of 20+ years. It has an industry-leading transferrable warranty that is not pro-rated. There are some other membranes that have some of these qualities. There are no other membranes that have all of these qualities.

EPDM is a single-ply sheet good that functions as a roofing membrane only, similarly to TPO and a torch down system. It would take another layer of product on top of these systems to convert them into a walking surface, and this would typically void any warranty. Duradek handles the roofing, waterproofing, and walking capabilities with its single-ply system. The cost of Duradek is about double that of the other systems. However, by the time a wear surface is added to the cost of these other systems the cost would be at least the same, but usually substantially more.

With fabric-backed reinforced vinyl such as Duradek, and non-woven backed vinyl, it is much easier to form into 90-degree transitions. At the same time, UV and Mold inhibitors are present throughout the entire thickness of the vinyl. Center reinforced vinyl typically does not form as well and only includes those inhibitors in the top layer of vinyl.

Duradek surfaces are a very low-maintenance decking solution, but homeowners do have some minimal maintenance responsibilities. The deck should be inspected annually to ensure all seals or caulking is intact. For best appearance, the deck should be cleaned seasonally (4 times a year). The textured surface is ideal for slip resistance but does provide a place for dirt to settle. For detailed information, see our Care and Cleaning page.

For detailed information, see our Care and Cleaning page. Also, download these 4 publications; Care and Cleaning Guide, Removing Mold from Duradek, Best Practices for Long Term Enjoyment and Winter Decking Considerations

It is very rare for Duradek to tear since it is fully adhered, but if this does ever happen, it can typically be repaired by your installer. See Duradek Case History #154 for a repair example.

Dogs love Duradek! This pet-friendly surface is durable enough to resist damage from scratching claws, more so than composite decks and vastly more than wood decks. It’s also easy to hose off any ‘accidents’ your fuzzies might have after sneaking bar-b-q bits from your friends all day. To keep fur-feet of all sizes comfortable, mid-range colors will hold less heat than darker colors and won’t show dirty paw prints as much as lighter options. Make sure to keep water and shade available and check out the ASPCA’s plant guide to make sure what’s in your planters won’t harm your pets. This will help make your vinyl deck a place the whole family can enjoy!

Duradek Ultra is 60 mil or 1.524 mm or 1/16″ thick.

Duradek seams are very resilient and not prone to leaking. Duradek waterproofing uses a 3-weld system with a 3/4″ seam overlap, back welded, then a main weld, and completing the seam with a cap weld. This makes a very resilient, waterproof continuous membrane.

Duradek can withstand most any natural heat conditions that nature would inflict upon it, including boiling water. But it will not withstand open flame or super-heated conditions like a fire pit or barbeque sitting directly on the deck.

The climate does not have an effect on the waterproofing performance of the vinyl, but it may affect the appearance of the vinyl (extreme UV exposure or pollution will age the appearance of the vinyl quicker, typically with fading the color of the print). However, all the products will outperform their 15-year warranty.

Duradek is excellent in a northern cold climate. It handles the freeze/thaw cycle very well and you can use de-icers on the deck surface. It will never crack like other deck coatings.

Duradek will not dent, and a chair leg will not tear the vinyl if it has plastic feet on it. Metal chairs with plastic feet will not be an issue, but sharp-edged metal feet should never be dragged across Duradek.

It is not appropriate as a kitchen flooring in a restaurant scenario, but it is great to use as flooring for outdoor kitchens or barbecue areas. It is very easy to clean.

Yes. A Polyester scrim reinforcement is embedded into the back of the vinyl.

The weight of the chairs is not much of an issue; it is more the edges of the chair feet that are a concern. Plastic deck chairs dragged across Duradek are very unlikely to cause any drag marks in the vinyl, but sharp-edged metal should never be dragged across Duradek. Metal chairs with plastic feet will not be an issue, but with a chair on any surface it is better to unseat yourself and move the chair than it is to ‘scoot’ the chair while you’re in it.

The Duradek is very flexible as much as it is strong. It is fully adhered to the substrate surface and will move with the expansion and contraction of the substrate.

Duradek handles the freeze/thaw cycle exceptionally well. Our membrane has excellent elasticity and elongation properties. Since it is fully adhered to the substrate, it expands and contracts with the surface with no issues at all. No chance of cracking, as with other deck surfaces.

Dropping a knife tip first will puncture the vinyl and cutting something on top of the vinyl will cause a cut mark. A puncture would likely not be an issue, but if a cut in the vinyl occurs, we recommend calling an applicator to do the repair with the hot air welder.

Although Saudi Arabia would be quite a harsh climate for PVC membranes because of the constant heat and UV exposure, Duradek would still perform for the 15 years that it is warranted. Duradek’ s cost comparison would be about double that of modified bitumen.

No, it would not be possible to install over an existing tiled surface. For an exterior tiled deck, the tile, grout and mortar are not the waterproof components.

A Duradek product called Tiledek Waterproof Membrane is adhered to a substrate, and mortar affixed tile and grout become the walking surface on the Tiledek.

Duradek provides the waterproofing requirements, the roofing requirements, and the walking surface on all substrates it covers, including decks/areas over living space.

Duradek is primarily a residential product but can be used in light commercial applications. For high traffic restaurants, you would want to consider a more durable wear surface.

The best substrate for Duradek is Untreated Exterior ACX grade T&G plywood. If the plywood is not T&G, then you will have to add blocking under the 8′ length of the plywood so that the edges of the individual sheets cannot move independently from each other. (See Techtalk #126 Plywood Sheathing and Deck Construction and Techtalk #126 Supplement on our Substrate Requirements page)

Yes Duradek can go over existing concrete. If a slope has to be created a floor leveling compound would be used to create the slope. (See Techtalk #140 Duradek Application to Concrete on our Substrate Requirements page)

Duradek can be installed on concrete in specific conditions (not “slab-on-grade”). It uses the same adhesives. Duradek can be installed on concrete substrates following our recommendations.

Yes, there are ways to build a “floating deck” on top of a membrane surface! And it’s also possible to dismantle an existing floating deck to repair or replace existing waterproof membranes that are underneath. We have done both.

Pavers can be applied on top of Duradek, which we call the Plazadek system. The applied wear surface should not be “fastened” into the Duradek membrane because it will create holes in the waterproofing. See assembly details in our Concrete Paver Overlay Drawing.

We would have to defer questions on the thin set mortar to their manufacturer. As already noted, it would be up to the thin set manufacturer to disclose how it will perform. But our recommendation is to ensure that the thin set being used is intended for exterior applications.

Whether you are looking to build a brand new waterproof deck or revitalize an existing one, Waterproof Decks Of Oregon is here to make your dreams a reality. Our team is excited to guide you through the entire process, from design and planning to construction and aftercare. Let us welcome you into our family of satisfied customers who have experienced the joy of outdoor living at its finest.

© Copyrights are Reserved by WPDecks.com | Website Developed by Rise Marketing